Motorcycle Frame Jig Kit: Build Your Chopper or Bobber with a Full Fixture

Embarking on a custom motorcycle build, whether a sleek bobber or a rebellious chopper, requires precision and stability. A motorcycle frame jig kit offers the perfect solution, providing a reliable fixture for welding and assembling your dream bike. This article delves into the world of motorcycle frame jigs, exploring their components, benefits, and the different types available, including the popular Chop Source frame jig.

Understanding the Motorcycle Frame Jig

What is a Frame Jig?

A frame jig is a specialized fixture used to make the frame of a motorcycle frame. It provides a stable platform to align and weld the various parts of the frame accurately. The motorcycle frame jig ensures that the neck, tubing, and other frame components are perfectly positioned before welding, resulting in a structurally sound and visually appealing motorcycle.

Components of a Motorcycle Frame Jig Kit

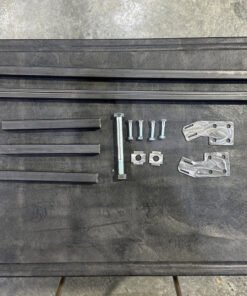

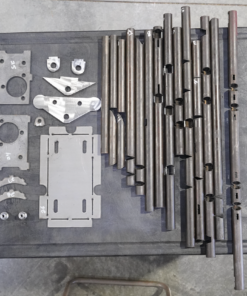

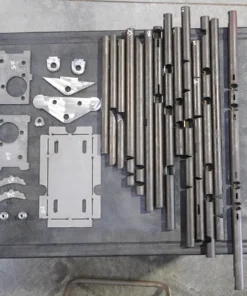

A motorcycle frame jig kit typically includes a variety of fixtures and brackets used to make the frame. These may include a neck fixture, axle plates, various mounting plates, and hardware. Structural tubing is often included for constructing the main frame structure. The kit may also feature neck cones and axle pins to ensure precise alignment during the welding process, which is crucial for a successful DIY build.

Benefits of Using a Frame Jig for Building

Using a frame jig for building offers several advantages including consistent frame geometry, which is crucial for handling and stability; it simplifies the welding process, reducing the risk of errors; and it enables the builder to create custom frames with greater precision and control. This is especially important for chopper and bobber builds, where unique frame designs are common.

Types of Motorcycle Frame Jigs

Full Motorcycle Frame Jig Kit Overview

A full motorcycle frame jig kit provides all the necessary components to construct a complete motorcycle frame. These kits often include a frame jig rotisserie, allowing the frame to rotate for easier welding access. Full kits are available for various motorcycle types, including rigid, softail, and hardtail frames. The kits may also include plans or instructions to guide the builder through the assembly process.

Chop Source Frame Jig Features

The Chop Source frame jig is a popular choice among custom motorcycle builders, known for its versatility and ease of use. The Chop Source frame jig often includes features like adjustable neck angle settings and interchangeable mounting plates, allowing builders to create a wide range of frame styles. These jigs are well-regarded in the Chop Source academy for their durability and precision.

Differences Between Chopper and Bobber Jigs

While both chopper and bobber frames can be built using a frame jig, there are some differences to consider. Chopper frame jigs often accommodate extended rake angles and longer frames, while bobber jigs may focus on shorter, more compact designs. The neck fixture and mounting points may also differ depending on the specific style of motorcycle being built, influencing the choice of welding jig.

Essential Parts and Accessories

Neck Cones and Their Importance

Neck cones are critical components included in the frame jig kit, ensuring precise alignment of the neck during the motorcycle frame jig build. These parts facilitate accurate neck placement, influencing the motorcycle’s handling and stability. Without properly aligned neck cones, the resulting frame may suffer from poor geometry, affecting the overall bike performance and requiring costly rework or frame straightening.

Using a Neck Fixture for Precision

A neck fixture is an invaluable tool when welding a motorcycle frame, providing a secure and adjustable fixture for the neck. It allows builders to set the desired rake and trail, essential for achieving specific handling characteristics for bobber, chopper, or any custom motorcycle. The neck fixture often includes features for fine-tuning, ensuring the neck is perfectly aligned before welding the frame tubing.

Understanding the Axle Plate and Pin Setup

The axle plate and pin setup is crucial for aligning the rear wheel and ensuring proper tracking of the motorcycle. Axle plates provide mounting points for the rear axle, while pins help maintain the correct spacing and alignment during the welding process. Precise placement of these parts is paramount for a safe and stable motorcycle, especially in a rigid or hardtail frame design.

DIY Frame Jig Construction

Materials Needed for Your Frame Jig

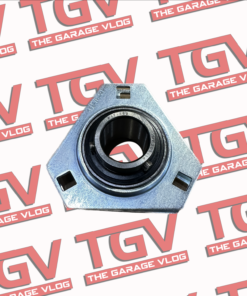

To embark on a DIY frame jig build, gathering the right materials is essential. Steel tubing forms the base structure, while plates provide stable mounting surfaces. Hardware such as bolts, nuts, and washers are necessary for assembly. Welding fixtures are available for purchase to simplify the process. The choice of metal greatly affects the frame’s strength and longevity, so quality is paramount.

Step-by-Step Plan to Build Your Own Jig

A step-by-step plan is crucial for a successful DIY frame jig project, starting with designing the frame jig to match your desired motorcycle frame dimensions, then cutting and welding the steel tubing to form the base structure, ensuring it is level and square. Purchase welding fixtures to support the neck fixture and axle plates. Finally, add adjustable fixtures and brackets used for versatile frame builds.

Using a Welding Jig for Stronger Joints

A welding jig is an indispensable tool for achieving strong and precise welds on your motorcycle frame by holding the frame components in place during welding, minimizing distortion and ensuring proper alignment. By using a welding jig, you can achieve professional-quality welds that are both visually appealing and structurally sound for your chopper fabrication parts.

Utilizing a Frame Jig Rotisserie

Benefits of a Rotisserie Stand for Welding

A frame jig rotisserie offers significant advantages when it comes to welding a motorcycle frame as this specialized stand allows you to easily rotate the frame 360 degrees, providing convenient access to all welding points. This eliminates the need to constantly reposition yourself or the frame, resulting in more consistent and higher-quality welds, a critical aspect of chopper fabrication parts.

How to Rotate Your Frame for Easy Access

The ability to rotate your motorcycle frame within a frame jig rotisserie is a game-changer for any DIY motorcycle build. Simply unlock the rotisserie mechanism and gently rotate the frame to the desired angle. This allows for comfortable and ergonomic welding, reducing fatigue and improving precision. A smooth rotation action ensures consistent weld bead placement, contributing to a stronger and more visually appealing frame.

Integrating a Digital Angle Finder for Accuracy

For ultimate precision, consider integrating a digital angle finder with your motorcycle frame jig. This tool allows you to accurately measure and set angles on the neck and other critical frame components. This is especially useful for achieving the desired rake and trail on a chopper or bobber build. Precision ensures optimal handling and stability of the finished bike.

Choosing the Right Frame Jig Kit

Factors to Consider When Selecting a Kit

When selecting a motorcycle frame jig kit, consider the type of frame you plan to build (e.g., rigid, softail, hardtail), the size of the motorcycle, and your welding experience. The kit should include all the necessary fixtures and brackets used, and the tubing should be of high quality steel. It is important to evaluate the quality and availability of chopper fabrication parts.

Comparing Available Kits on the Market

The market offers a variety of motorcycle frame jig kits, each with its own strengths and weaknesses. The Chop Source frame jig is known for its versatility and ease of use. Compare the features, price, and reviews of different kits to find the one that best suits your needs. It is important to check the sale prices for the complete system.

Building vs. Buying: What’s Best for You?

Deciding whether to build your own frame jig or purchase a pre-made kit depends on your skills, resources, and time constraints. Building a DIY frame jig can save money but requires significant welding and fabrication experience. A pre-made motorcycle frame jig kit offers convenience and precision but comes at a higher cost. Consider your priorities and choose the option that best aligns with your goals and capabilities.

Be the first to review “WIY Motorcycle Frame jig” Cancel reply

Related products

Parts

Parts

Parts

Reviews

There are no reviews yet.